SECTION

BUCK-BOOST TRANSFORMERS

ACME ELECTRIC

•

MILWAUKEE, WI

•

800.334.5214

•

acmetransformer.com

90

Operation and Construction

7. Why do buck-boost transformers have 4

windings?

To make them versatile!

A four winding buck-boost transformer

(2 primary and 2 secondary windings) can be connected

eight different ways to provide a multitude of voltage and kVA

outputs. A two winding (1 primary & 1 secondary) buck-boost

transformer can be connected only one way.

8. Will a buck-boost transformer

stabilize voltage?

No.

The output voltage is a function of the input voltage. If the

input voltage varies, then the output voltage will also vary by

the same percentage.

Load Data

9. Are there any restrictions on the type

of load that can be operated from a

buck-boost transformer?

No

, there are no restrictions.

10. Why can a buck-boost transformer

operate a kVA load many times larger than the

kVA rating on its nameplate?

Since the transformer has been auto-connected in such a

fashion that the 22V secondary voltage is added to the 208V

primary voltage, it produces 230V output.

The autotransformer kVA is calculated:

kVA = Output Volts x Secondary Amps

1000

kVA = 230 V x 41.67 Amps = 9.58 kVA

1000

3. What is the difference between a buck-

boost transformer and an autotransformer?

When a primary lead wire and secondary lead wire of a buck-

boost transformer are connected together electrically, in a

recommended voltage bucking or boosting connection, the

transformer is in all respects, an autotransformer. However,

if the interconnection between the primary and secondary

winding is not made, then the unit is an insulating type

transformer.

Applications

4. Why are they used?

Electrical and electronic equipment is designed to oper-

ate on standard supply voltage. When the supply voltage is

constantly too high or too low, (usually more than 55%), the

equipment fails to operate at maximum efficiency. A buck

and boost transformer is a simple and ECONOMICAL means

of correcting this off-standard voltage.

5. What are the most common applications

for buck-boost transformers?

Boosting 208V to 230V or 240V and vice versa for commer-

cial and industrial air conditioning systems; boosting 110V to

120V and 240V to 277V for lighting systems; voltage correc-

tion for heating systems and induction motors of all types.

Many applications exist where supply voltages are constantly

above or below normal.

6. Can buck-boost transformers be used to

power low voltage circuits?

Yes

, low voltage control, lighting circuits, or other low voltage

applications requiring either 12V, 16V, 24V, 32V or 48V. The

unit is connected as an insulating transformer and the name-

plate kVA rating is the transformer’s capacity.

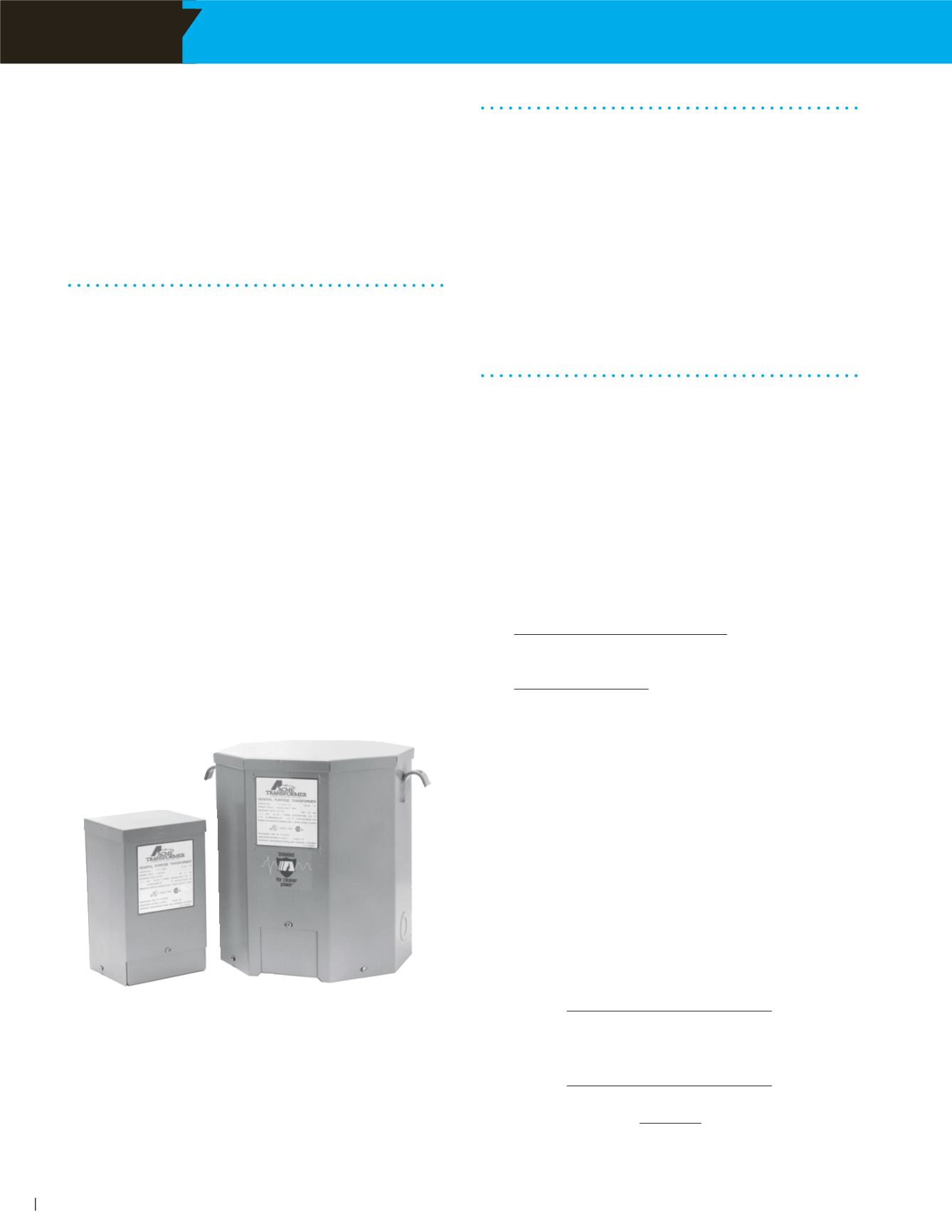

The picture to the left illustrates the difference in physical size between

the autotransformer of 1 kVA, capable of handling a 9.58 kVA load, and

an isolation transformer capable of handling a 7.5 kVA load.

To cite an example... a model T111683 buck-boost transformer has a

nameplate kVA rating of 1 kVA, but when it’s connected as an autotrans-

former boosting 208V to 230V, its kVA capacity increases to 9.58 kVA.

The key to understanding the operation of buck-boost transformers lies

in the fact that the secondary windings are the only parts of the trans-

former that do the work of transforming voltage and current. In the example

above, only 22 volts are being transformed (boosted) — i.e. 208V + 22V

= 230V. This 22V transformation is carried out by the secondary windings

which are designed to operate at a maximum current of 41.67 amps

(determined by wire size of windings).

Maximum Secondary Amps =

nameplate kVA x 1000

secondary volts

Maximum Secondary Amps =

1.0 kVA x 1000

24 V

1000 VA = 41.67 amps

24 V

(1 kVA) T111683 (7.5 kVA) T2535153S

=