12

toll free 800.334.5214 ACME ELECTRIC |

hubbell-acmeelectric.comQ u e s t i o n s a n d A n s w e r s

The underlying problem is low voltage at the motor terminals. If the ampere rating of the motor and transformer overcurrent device falls

within the motor’s 50%RPM draw requirements, a problem is likely to develop. The overcurrent device may not open under intermediate

motor ampere loading conditions. Overheating of the motor and/or transformer would occur, possibly causing failure of either component.

This condition is more pronounced when one transformer is used to power one motor and the running amperes of the motor is

in the vicinity of the full load ampere rating of the transformer. The following precautions should be followed:

(1)

When one transformer is used to operate one motor, the running amperes of the motor should not exceed 65% of the

transformer’s full load ampere rating.

(2)

If several motors are being operated from one transformer, avoid having all motors start at the same time. If this is impractical,

then size the transformer so that the total running current does not exceed 65% of the transformer’s full load ampere rating.

35. Why are Small Distribution Transformers not used for Industrial Control Applications?

Industrial control equipment demands a momentary overload capacity of three to eight times normal capacity. This is most

prevalent in solenoid or magnetic contactor applications where inrush currents can be three to eight times as high as normal sealed

or holding currents but still maintain normal voltage at this momentary overloaded condition. Distribution transformers are designed

for good regulation up to 100 percent loading, but their output voltage will drop rapidly on momentary overloads of this type making

them unsuitable for high inrush applications.

Industrial control transformers are designed especially for maintaining a high degree of regulation even at eight times

normal load.This results in a larger and generally more expensive transformer. For a complete listing of ACME industrial control

transformers, refer to Section 6.

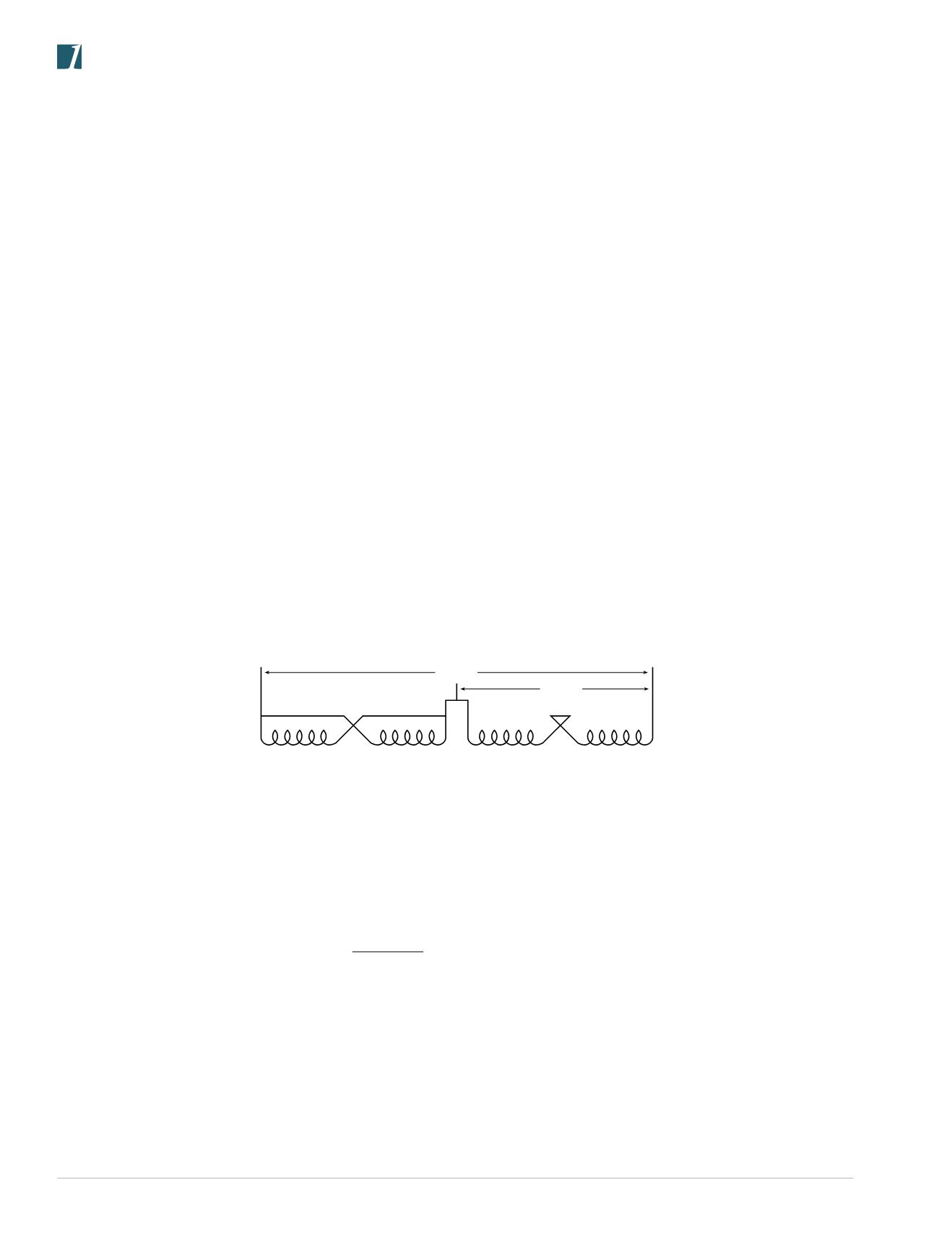

36. Can 4-Winding Single Phase Transformer be auto-connected?

Yes. There are occasions where 480 volts single phase can be stepped down to 240 volts single phase by autoconnecting a

standard 4-winding isolating transformer as shown in Figure 1. If connected in this manner, the nameplate kVA is doubled. For

example: A 10 kVA load can be applied to a 5 kVA 4-winding transformer if connected per Figure 1.

Figure 1

H1

480V

H3 H2 H4 X1 X3 X2 X4

240V

37. What about balanced loading on Three Phases?

Each phase of a three phase transformer must be considered as a single phase transformer when determining loading. For

example: A 45 kVA three phase transformer with a 208Y/120 volt secondary is to service 4 loads at 120 volts single phase each.

These loads are 10 kVA, 5 kVA, 8 kVA,and 4 kVA.

Note:

that maximum loading on any phase does not exceed 10 kVA. Each phase has a 15 kVA capacity.

45kVA

= 15kVA per phase

3 phase

If incorrect method is used, phase B will have an 18 kVA load which is 3 kVA above its normal capacity of 15 kVA and failure will

result even though we only have a total load of 27 kVA on a 45 kVA transformer.

38. What is meant by “Balanced Loading” on Single Phase Transformer applications?

Sincemost singlephase transformers have a secondaryvoltage of 120/240, theywill be operatedas a threewire system. Caremust be taken in

properly distributing the loadas the transformer secondary consists of 2 separate 120 volt windings. Each 120 volt winding is ratedat one-half the

nameplate kVA rating. For example: A10 kVA transformer, 120/240 volt secondary is to service an 8 kVA loadat 240 volts and two 1 kVA loads at

120 volts each.