169

toll free 800.334.5214 ACME ELECTRIC |

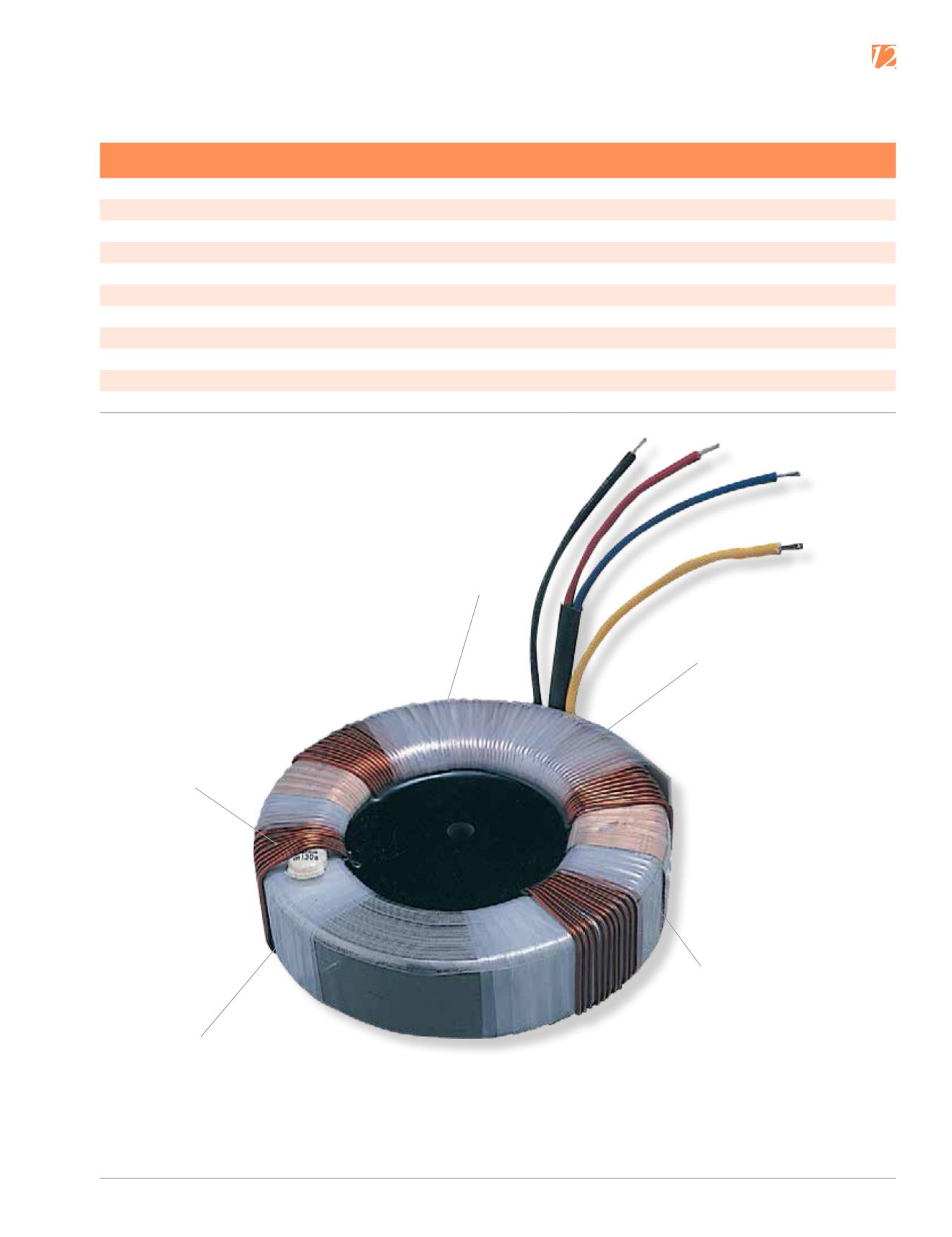

hubbell-acmeelectric.comA m v e c o T o r o i d a l S o l u t i o n s

OVERALL COMPARISON OF 250VA E-I CORE ISOLATION TRANSFORMER VS. 250 VA TOROIDAL ISOLATION TRANSFORMER

Feature

250VA E-I Core Transformer

250VA Toroid Transformer

Height

4.7" (119mm)

2.2" (56mm)

Width

3.9" (99mm)

4.5" (114mm)

Depth

4.3" (109mm)

4.5" (114mm)

Volume

78.8

sqs.in. (508.4cm2)

35.0

sq.in. (225.8cm2)

Weight

10 lbs. (4.5 kg)

5 lbs. (2.3 kg)

Mounting Requirements

Four corner bolts

Sinle bolt through center

No Load Losses

10.0 W

1.5 W

Continuity of Magnetic Path

50% of grain perpendicular

100% parallel grain orientation

Air Gaps

Approximately 180 (60 laminations x 3)

None

Magnetic Properties of Core

Affected by clamping, welding, banding, etc.

Optimized prior to winding and remains stable

Coupling Factor

Limited by bobbin width and layers of windings

Maximized by even winding distribution and close proximity to core

Primary to Secondary Insulation

Polyester film-Class B (130˚C)

Four layers minimum between windings

Meets test requirement of 4000V RMS for

1 minute between primary and secondary

Windings

Base coat of Polyester. Heavy

topcoat of amide imide (200˚C)

Wound uniformly over entire core

Better heat dissipation

Windings configured for minimum

flux leakage

Low voltage maintained between

adjacent turns

Core Insulation

All cores: 100% surface coverage of four layers

of 2 mil polyester film Class B (130˚C)

Protects, insulates and cushions the core from

windings and reduces vibration

Core

Cores are manufactured and annealed

in-house, under controlled conditions

Continuous tightly wound grain oriented

silicon steel...no airgaps, no mechanical

noise

Lathed radial corners... compact design,

most efficient use of materials

No core caps necessary

Outer Insulation

Tape wound type: Standard two layers

polyester film Class B (130˚C)

Magnetic enclosures optional