5

59

toll free 800.334.5214 ACME ELECTRIC |

hubbell-acmeelectric.comD r i v e I s o l a t i o n T r a n s f o r m e r s a n d A C L i n e R e a c t o r s

ACME ADVANTAGE

Wound Cores and Strip Winding mean lower losses

All Acme DITs above 7.5 kVA are wound with strip windings to ensure the lowest possible eddy current losses. All our DITs

440 kVA and larger use stacked core. This superior design has very low losses and quiet operation. Both of these features

combine to significantly reduce losses and operating costs compared to other types of constructions.

Copper terminations provide trouble-free operation

All Acme DITs up to and including 220 kVA have copper terminations. The transition from aluminum strip coil conductors to

copper terminations is accomplished by a bonding process known as “Koldwelding

™

”. This process has been used by Acme

for over 25 years to provide a trouble-free, permanent bonding of the two metals.

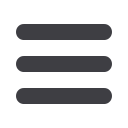

Wound core construction showing all copper terminations